Air filters play a crucial role in maintaining air quality in air-cooled environments. Here's how they contribute:

1.Particle Removal: Air filters serve as the first line of defense against airborne particles and contaminants. They utilize various filtration media to trap and retain particulate matter, including dust, allergens, pollen, and microorganisms. This filtration process is crucial for preserving indoor air quality, particularly in spaces where occupants may be sensitive to allergens or pollutants. By effectively capturing these particles, air filters prevent them from circulating within the indoor environment and potentially causing respiratory discomfort or health issues.

2.Improved Respiratory Health: The removal of airborne particles through air filtration contributes significantly to enhanced respiratory health. Clean, filtered air reduces the likelihood of individuals inhaling irritants that can trigger allergies or aggravate existing respiratory conditions such as asthma or bronchitis. For businesses and organizations, this can translate into a healthier and more productive workforce, as employees are less likely to experience health-related absenteeism.

3.Reduced Odors: In various settings, including commercial spaces, manufacturing facilities, and restaurants, unwanted odors can be a concern. Air filters, depending on their design and capabilities, can adsorb or neutralize odorous compounds, making the indoor environment more pleasant for occupants. This is especially important in industries where specific processes or chemicals generate strong and potentially noxious odors.

4.Protection of Equipment: In industrial settings, air-cooling systems are often used to regulate temperatures in machinery and equipment. Air filters play a vital role in safeguarding this equipment by preventing the accumulation of dust and debris on sensitive components. The accumulation of particles on heat exchangers, coils, or electronic components can lead to reduced operational efficiency and even equipment failure. Clean air filters are essential for maintaining equipment longevity and reducing maintenance costs.

5.Prevention of Airborne Contaminants: Certain industries, such as chemical manufacturing or pharmaceutical production, may encounter airborne contaminants that pose health and safety risks to occupants. Specialized air filters, such as High Efficiency Particulate Air (HEPA) filters or chemical-specific filters, are employed to capture and remove these hazardous substances from the air supply. This not only ensures the safety of personnel but also helps maintain compliance with stringent regulatory requirements.

6.Enhanced Cooling Efficiency: Air filters contribute to the overall efficiency of air-cooling systems. When filters become clogged with accumulated particles, airflow is impeded, and the cooling system must work harder to achieve the desired temperature. This results in reduced cooling efficiency, increased energy consumption, and higher operational costs. Regular inspection and replacement of air filters are essential maintenance practices to ensure optimal system performance and energy efficiency.

7.Compliance with Regulations: Many industries are subject to regulations and standards governing indoor air quality and emissions. By employing appropriate air filtration solutions, businesses can ensure compliance with these regulations, thereby avoiding potential fines, legal liabilities, and reputational damage. Compliance not only protects the health and well-being of occupants but also upholds corporate responsibility and sustainability objectives.

8.Energy Efficiency: Clean air filters contribute to energy savings by allowing air-cooling systems to operate at their designed efficiency levels. Reduced airflow due to clogged filters can result in higher energy consumption as the cooling system compensates for the restriction. By maintaining clean filters and optimizing airflow, organizations can achieve energy-efficient operations, reducing their environmental footprint and operational costs.

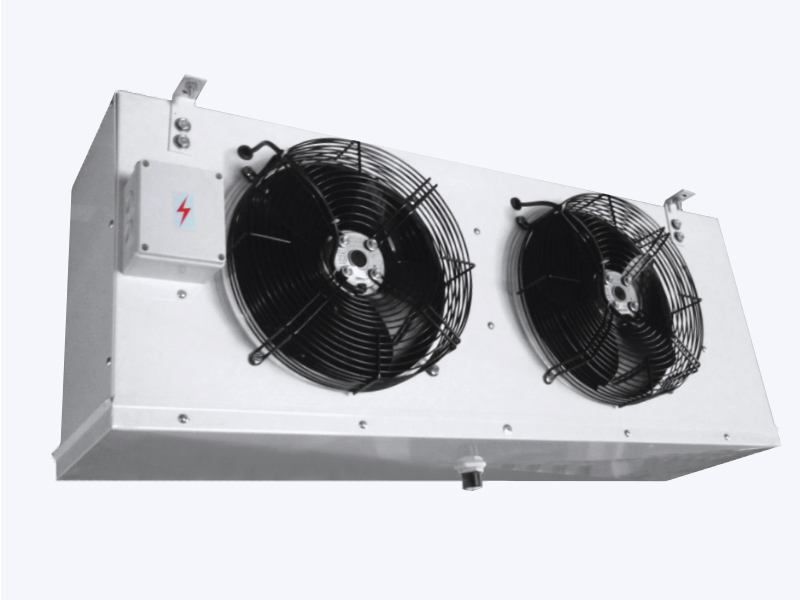

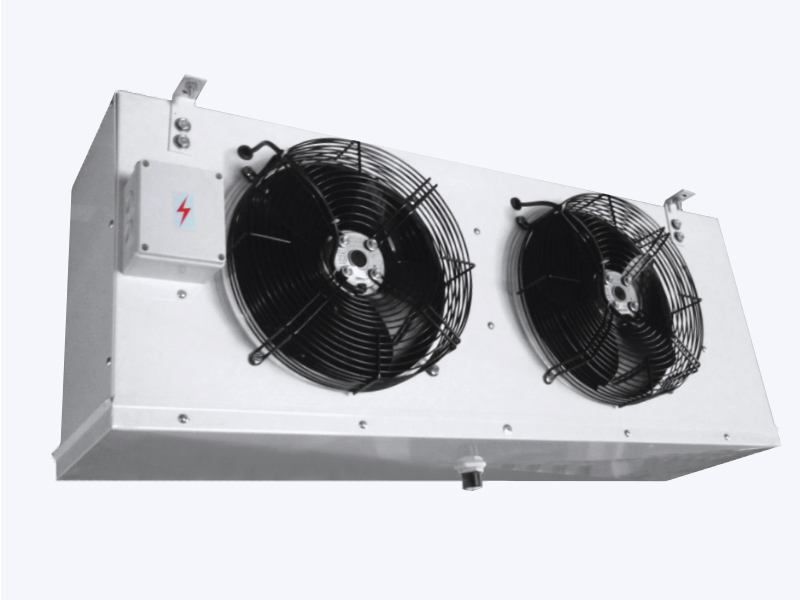

D serial Air cooler units can be applicable to all Ranges of Cold room, It includes DL, DD and DJ three styles, respectively apply to diferent temperature cold room. Its' advantage are: Compact, light, cold room area save. Compare to the normal flow unit cooler, It can rapidly pull down the cold room temperature, greatly in preserve the fresh product.

English

English عربى

عربى 简体中文

简体中文