The energy consumption implications of using a semi-hermetic compressor can vary depending on several factors:

Efficiency: Semi-hermetic compressors are engineered with precision to optimize the compression process, resulting in higher efficiency levels compared to open-type compressors. This efficiency is achieved through advanced design features such as improved sealing, reduced internal leakage, and enhanced heat transfer capabilities. As a result, semi-hermetic compressors can achieve greater cooling or refrigeration output per unit of energy input, bring about reduced energy consumption and operational costs over time.

Variable Speed Technology: Some semi-hermetic compressors are equipped with variable speed drive (VSD) technology, which allows them to adjust their operating speed in response to changes in cooling demand. By dynamically modulating compressor speed to match system requirements, VSD-equipped semi-hermetic compressors can operate more efficiently across a wide range of operating conditions. This adaptive control strategy minimizes energy wastage during periods of partial load or low demand, thereby peak overall system efficiency and energy savings.

System Design: The energy consumption of a refrigeration or HVAC system utilizing a semi-hermetic compressor is influenced not only by the compressor itself but also by the holistic design of the entire system. Factors such as the selection and sizing of ancillary components (e.g., evaporators, condensers, expansion valves), the configuration of refrigerant piping and distribution, and the implementation of advanced control algorithms all play critical roles in determining overall energy efficiency. A well-designed system ensures positive matching of components, minimizes pressure drops, maximizes heat transfer efficiency, and optimizes system performance for reduced energy consumption.

Operating Conditions: The operating conditions under which a semi-hermetic compressor operates can significantly impact its energy efficiency. Ambient temperature, evaporator and condenser temperatures, suction and discharge pressures, and system load requirements all influence compressor performance. Properly sizing and selecting the compressor for the specific application, as well as ensuring adequate ventilation and airflow around the compressor, are essential for optimizing energy efficiency under varying operating conditions. Advanced controls and monitoring systems can help optimize compressor operation in real-time, further enhancing energy performance.

Maintenance: Regular and proactive maintenance practices are crucial for preserving the energy efficiency of semi-hermetic compressors over their operational lifespan. Routine tasks such as cleaning evaporator and condenser coils, checking refrigerant charge levels, inspecting and replacing air filters, and lubricating moving parts help ensure positive compressor performance and energy efficiency. Addressing issues such as refrigerant leaks, worn seals, or damaged components promptly can prevent energy wastage and maintain system integrity. Conducting periodic performance assessments and efficiency audits can identify opportunities for optimization and energy savings.

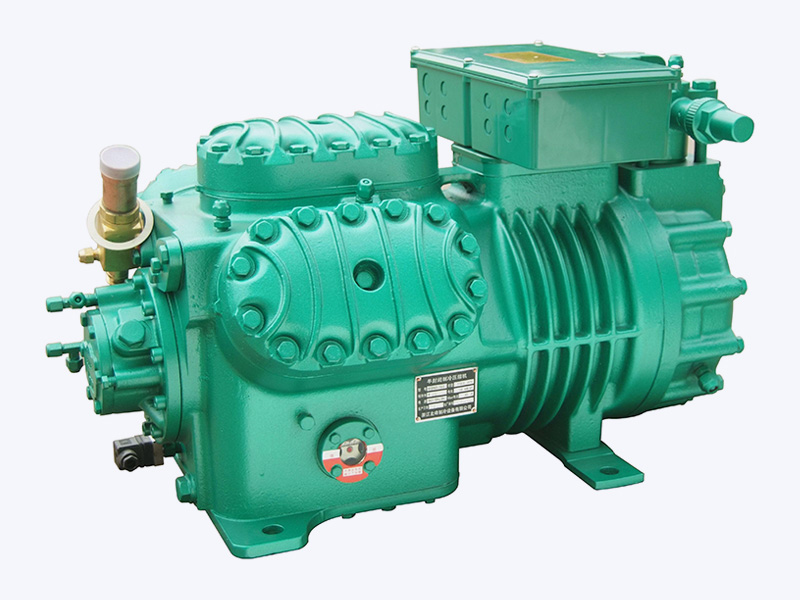

Semi-Hermetic Compressor(15HP-50HP)

English

English عربى

عربى 中文简体

中文简体