Capacity Control Mechanisms: Semi-hermetic compressors often incorporate sophisticated capacity control mechanisms, such as unloading valves and cylinder deactivation, to manage varying loads effectively. Unloading valves can bypass a portion of the refrigerant within the compressor, reducing its capacity without shutting down completely. Cylinder deactivation involves temporarily disabling some of the cylinders within the compressor, effectively reducing the compression capacity. These mechanisms allow the compressor to operate efficiently at partial loads, optimizing energy use and minimizing operational costs. By avoiding excessive cycling, these controls also reduce the risk of mechanical failures and extend the lifespan of the compressor.

Modulation Control: Modulation control is a technique used to fine-tune the compressor’s capacity in response to changing load conditions. This can be achieved through methods such as variable suction pressure control or implementing a hot gas bypass system. By adjusting the suction pressure, the compressor can modulate its capacity, providing just the right amount of cooling or heating needed. A hot gas bypass system can redirect a portion of the discharge gas back to the suction side, effectively reducing the load on the compressor. These modulation techniques ensure a more stable and efficient operation, preventing the compressor from cycling on and off too frequently, which can lead to increased energy consumption and wear.

Advanced Control Systems: Modern semi-hermetic compressors are equipped with advanced control systems that continuously monitor key operational parameters, such as suction and discharge pressures, temperatures, and motor current. These control systems utilize sophisticated algorithms to analyze real-time data and make precise adjustments to the compressor’s operation. For example, if the control system detects a drop in suction pressure, it can increase the compressor speed or adjust the capacity control mechanisms to maintain optimal performance. This level of control ensures that the compressor operates efficiently under varying load conditions, reducing energy consumption and enhancing reliability.

Staging Multiple Compressors: In large HVAC and refrigeration systems, multiple semi-hermetic compressors are often used in a staged configuration to handle varying loads. This approach involves bringing compressors online or taking them offline based on the current demand. For example, during peak load conditions, all compressors may be operational to meet the high demand. Conversely, during low load periods, some compressors can be turned off, while others operate at reduced capacity. Staging ensures that the system only uses the necessary amount of energy, optimizing efficiency and reducing wear on the individual compressors. This approach provides redundancy, improving system reliability and ensuring continuous operation even if one compressor fails.

Load Shedding: Load shedding is a strategy used to balance the load on the compressor by temporarily shutting down or reducing the capacity of certain system components during periods of low demand. For example, in a multi-zone HVAC system, load shedding might involve reducing the cooling output in unoccupied zones or lowering the setpoints in non-critical areas. This approach helps prevent overloading the compressor and reduces unnecessary energy consumption. By carefully managing the load, load shedding ensures efficient operation, minimizes wear and tear on the compressor, and extends its operational life.

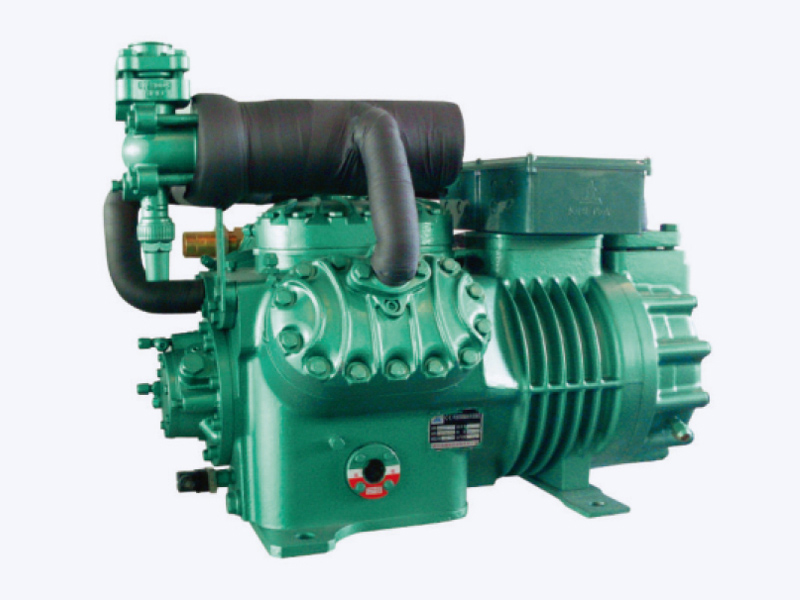

Semi-Hermetic Two-Stage Compressor

English

English عربى

عربى 简体中文

简体中文

.jpg?imageView2/2/w/300/h/300/format/webp/q/75)