Installing an air-cooled condenser requires careful consideration of venting and airflow to ensure optimal performance and efficiency. Here are the typical installation requirements and considerations:

Clearance Space: Adequate clearance around the air-cooled condenser is critical to ensure optimal airflow and efficient heat exchange. Manufacturers typically recommend specific clearance distances to prevent obstruction of air intake and discharge pathways. This clearance is essential to maintain the condenser's rated capacity and prevent airflow restriction, which can lead to reduced efficiency and increased energy consumption. Proper clearance also facilitates ease of maintenance, allowing technicians to access coils, fans, and other components for inspection and cleaning.

Orientation: The orientation of the air-cooled condenser affects its ability to expel heat effectively. It should be positioned to allow natural airflow through the coil fins without obstruction. This typically means placing the condenser in a location where prevailing winds or natural convection currents can assist in heat dissipation. Correct orientation minimizes the risk of recirculating heated air and maximizes the efficiency of the condenser unit. Proper orientation helps mitigate issues such as hot spots and uneven cooling across the condenser coil surface, which can impact overall system performance and longevity.

Airflow Path: Maintaining a clear and unobstructed airflow path around the condenser is essential for optimal performance. Any obstruction, such as nearby structures, equipment, or vegetation, can disrupt airflow patterns and hinder heat dissipation. This obstruction increases resistance to airflow, which forces the condenser to work harder to achieve the desired cooling effect. To ensure uninterrupted airflow, it's crucial to regularly inspect and clear the area around the condenser of any debris or objects that could impede airflow. This proactive approach minimizes the risk of overheating, reduces energy consumption, and extends the operational life of the condenser.

Ventilation: Adequate ventilation around the installation site is paramount for dissipating the heat expelled by the air-cooled condenser. Insufficient ventilation can lead to the accumulation of hot air around the condenser unit, diminishing its cooling efficiency and potentially causing overheating. Proper ventilation allows ambient air to flow freely around the condenser, facilitating heat transfer and maintaining optimal operating temperatures. This ventilation can be achieved through strategically placed vents or openings in the surrounding structures, ensuring a continuous supply of fresh air for cooling purposes.

Elevation: The elevation of the condenser installation plays a crucial role in optimizing airflow and heat dissipation. Installing the condenser at an appropriate height above ground level helps facilitate natural convection currents, allowing hot air to rise away from the unit. This elevation reduces the risk of recirculation, where heated air is drawn back into the condenser intake, compromising cooling efficiency. Elevated installation helps prevent the condenser from drawing in dust, debris, or other contaminants from ground level, which can obstruct airflow and impair performance over time.

Environmental Considerations: When selecting an installation site for the air-cooled condenser, it's essential to consider environmental factors that may impact its performance. Factors such as prevailing wind direction, nearby structures, and ambient temperature variations can influence airflow patterns and heat dissipation efficiency. A thorough environmental assessment helps identify potential obstacles or challenges that could affect the condenser's operational effectiveness. By choosing a site that minimizes these environmental disruptions, you can enhance the condenser's reliability, maintain consistent cooling performance, and optimize energy efficiency throughout its service life.

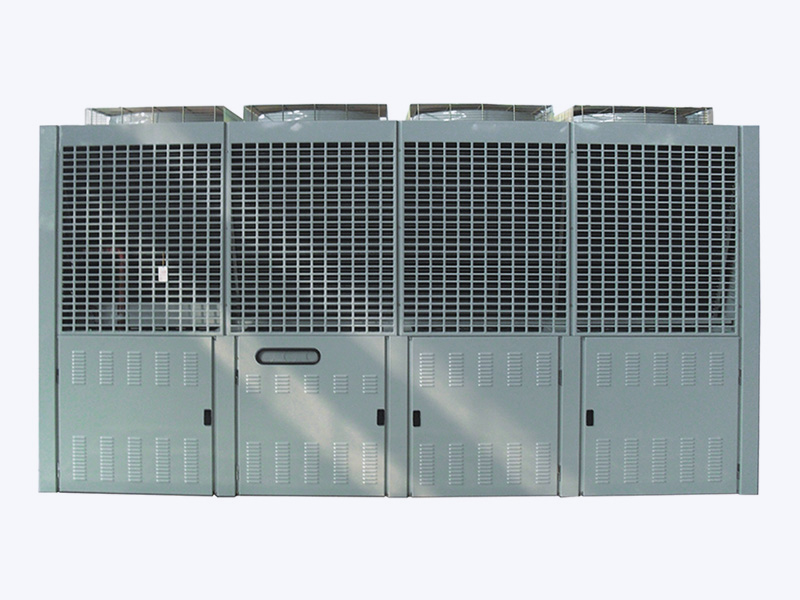

Cabinet-Style V Type Condenser

English

English عربى

عربى 简体中文

简体中文