The size and capacity of a semi-hermetic compressor play crucial roles in determining its performance in various cooling or refrigeration systems. Here's how:

Cooling/Refrigeration Load Matching: Achieving precise load matching between the semi-hermetic compressor and the cooling or refrigeration system entails a comprehensive analysis of various factors. These factors include the thermal characteristics of the space or product being cooled, ambient conditions, required temperature setpoints, and potential load fluctuations. Engineers often utilize heat load calculations, taking into account heat transfer coefficients, thermal conductivity, and specific heat capacities of materials involved. They consider dynamic factors such as peak demand periods, seasonal variations, and potential future expansions or modifications to ensure the compressor's capacity aligns optimally with the system's requirements. Failure to accurately match the compressor's capacity with the load can result in inefficient operation, excessive energy consumption, inadequate cooling, and compromised system performance.

Efficiency: The efficiency of a semi-hermetic compressor is intricately tied to its operating conditions, including load, temperature differentials, refrigerant type, and system design. Selecting the right compressor size ensures that it operates within its optimal efficiency range, maximizing energy efficiency and minimizing operational costs. Engineers analyze compressor performance data, including volumetric and isentropic efficiency curves, to identify the most efficient operating points for specific applications. Advancements in compressor technology, such as variable speed drives and digital modulation techniques, offer opportunities to further enhance efficiency by matching compressor capacity to varying load conditions dynamically. Properly sized compressors not only reduce energy consumption but also minimize environmental impact by lowering greenhouse gas emissions associated with refrigerant usage and electricity generation.

System Performance: The capacity of the semi-hermetic compressor directly influences several key performance metrics of the cooling or refrigeration system. Engineers evaluate system performance criteria such as temperature stability, pull-down times, temperature recovery rates, and overall cooling capacity to ensure optimal operation. Properly sized compressors facilitate rapid temperature stabilization and maintain consistent temperatures within the desired range, essential for preserving product quality, ensuring process integrity, and meeting regulatory requirements. They contribute to system reliability by providing sufficient cooling capacity to handle peak loads and unexpected demand surges without compromising performance or risking equipment damage. Achieving desired system performance requires meticulous attention to detail during compressor selection, system design, installation, and commissioning processes.

System Cycling: Effective control of system cycling is critical for maximizing energy efficiency, minimizing wear on components, and ensuring reliable operation of the cooling or refrigeration system. Engineers aim to balance compressor runtime with off-cycle periods to optimize energy consumption and maintain stable temperatures. Oversized compressors can lead to frequent short cycling, characterized by rapid on-off cycling intervals, which not only increase energy consumption but also impose mechanical stresses on the compressor, reducing its lifespan. Conversely, undersized compressors may run continuously, struggling to meet cooling demands and consuming excessive energy. Properly sized compressors exhibit controlled cycling behavior, striking a balance between energy efficiency and system stability.

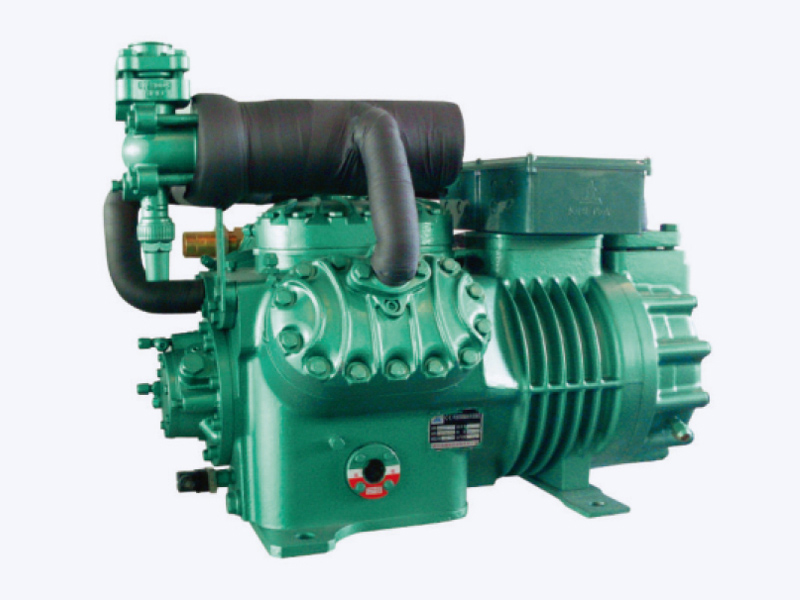

Semi-Hermetic Two-Stage Compressor

The same serial compressors are available for many kinds of refrigerants such as R134a, R404a, R407C and R22

The same serial compressors are suitable for different operating temperatures.

English

English عربى

عربى 简体中文

简体中文