The capacity of a screw-type condensing unit plays a crucial role in determining its suitability for different environments. Here's how:

Cooling Demand: The capacity of a screw-type condensing unit is fundamental to meeting the diverse cooling demands of different environments. For large commercial buildings, such as shopping malls or office complexes, where the cooling load can be substantial due to factors like occupancy, heat-generating equipment, and solar gain, a condensing unit with a high capacity is essential. Similarly, in industrial facilities where processes generate significant heat, such as manufacturing plants or data centers, a robust condensing unit capable of handling intense cooling requirements is imperative to ensure operational efficiency and employee comfort. Understanding the specific cooling demands of each environment is crucial for selecting the appropriate capacity of the condensing unit to maintain optimal conditions effectively.

Temperature Variations: Environments subjected to wide temperature variations throughout the year demand condensing units that can adapt to fluctuating conditions seamlessly. In regions with extreme climates, such as desert areas experiencing scorching summers and frigid winters, or locations prone to temperature swings between day and night, the capacity of the condensing unit becomes paramount. A higher capacity unit offers greater flexibility to cope with temperature differentials, ensuring consistent cooling performance regardless of external weather conditions. This adaptability is particularly critical for environments where temperature control is vital, such as server rooms, laboratories, or medical facilities, where maintaining stable conditions is essential for equipment operation or specimen preservation.

Space Constraints: The physical footprint of a condensing unit must align with the available space in the installation area. In environments where space is limited, such as urban settings or retrofit projects, selecting a condensing unit with an appropriate capacity that fits within the allocated space is essential. Oversized units may pose challenges during installation, requiring modifications to accommodate their size or impacting the layout of existing infrastructure. Conversely, undersized units may compromise cooling efficiency or necessitate the use of multiple units to meet desired cooling load, potentially increasing installation complexity and operational costs.

Energy Efficiency: Optimizing energy efficiency is a primary concern for users seeking to minimize operating costs and reduce environmental impact. Properly sizing the capacity of the condensing unit is critical to achieving optimal energy performance. An oversized unit may cycle on and off frequently, leading to inefficient operation and increased energy consumption. This phenomenon, known as short cycling, not only wastes energy but also places unnecessary strain on system components, potentially shortening their lifespan. Conversely, an undersized unit may operate continuously at maximum capacity to meet the cooling demand, consuming more energy than necessary and driving up utility bills. By selecting a condensing unit with the right capacity for the specific cooling requirements of the environment, users can maximize energy efficiency, reduce operational costs, and minimize their carbon footprint.

Load Fluctuations: Environments characterized by fluctuating cooling loads require condensing units capable of adapting to varying demand levels efficiently. Retail spaces, for example, experience fluctuations in occupancy and heat load throughout the day, with peak demand occurring during busy periods such as weekends or holidays. Similarly, data centers may experience variable cooling loads depending on factors like server utilization and ambient temperature. In such dynamic environments, selecting a condensing unit with sufficient capacity to handle peak demands without sacrificing efficiency during periods of lower demand is essential. Properly sizing the unit ensures that it can modulate its cooling output to match the fluctuating load, optimizing energy consumption and maintaining stable conditions within the environment.

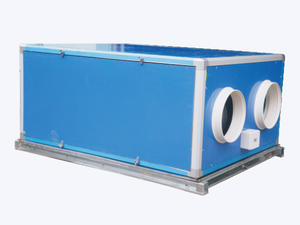

Screw-Type Condensing Unit

Cooling Demand: The capacity of a screw-type condensing unit is fundamental to meeting the diverse cooling demands of different environments. For large commercial buildings, such as shopping malls or office complexes, where the cooling load can be substantial due to factors like occupancy, heat-generating equipment, and solar gain, a condensing unit with a high capacity is essential. Similarly, in industrial facilities where processes generate significant heat, such as manufacturing plants or data centers, a robust condensing unit capable of handling intense cooling requirements is imperative to ensure operational efficiency and employee comfort. Understanding the specific cooling demands of each environment is crucial for selecting the appropriate capacity of the condensing unit to maintain optimal conditions effectively.

Temperature Variations: Environments subjected to wide temperature variations throughout the year demand condensing units that can adapt to fluctuating conditions seamlessly. In regions with extreme climates, such as desert areas experiencing scorching summers and frigid winters, or locations prone to temperature swings between day and night, the capacity of the condensing unit becomes paramount. A higher capacity unit offers greater flexibility to cope with temperature differentials, ensuring consistent cooling performance regardless of external weather conditions. This adaptability is particularly critical for environments where temperature control is vital, such as server rooms, laboratories, or medical facilities, where maintaining stable conditions is essential for equipment operation or specimen preservation.

Space Constraints: The physical footprint of a condensing unit must align with the available space in the installation area. In environments where space is limited, such as urban settings or retrofit projects, selecting a condensing unit with an appropriate capacity that fits within the allocated space is essential. Oversized units may pose challenges during installation, requiring modifications to accommodate their size or impacting the layout of existing infrastructure. Conversely, undersized units may compromise cooling efficiency or necessitate the use of multiple units to meet desired cooling load, potentially increasing installation complexity and operational costs.

Energy Efficiency: Optimizing energy efficiency is a primary concern for users seeking to minimize operating costs and reduce environmental impact. Properly sizing the capacity of the condensing unit is critical to achieving optimal energy performance. An oversized unit may cycle on and off frequently, leading to inefficient operation and increased energy consumption. This phenomenon, known as short cycling, not only wastes energy but also places unnecessary strain on system components, potentially shortening their lifespan. Conversely, an undersized unit may operate continuously at maximum capacity to meet the cooling demand, consuming more energy than necessary and driving up utility bills. By selecting a condensing unit with the right capacity for the specific cooling requirements of the environment, users can maximize energy efficiency, reduce operational costs, and minimize their carbon footprint.

Load Fluctuations: Environments characterized by fluctuating cooling loads require condensing units capable of adapting to varying demand levels efficiently. Retail spaces, for example, experience fluctuations in occupancy and heat load throughout the day, with peak demand occurring during busy periods such as weekends or holidays. Similarly, data centers may experience variable cooling loads depending on factors like server utilization and ambient temperature. In such dynamic environments, selecting a condensing unit with sufficient capacity to handle peak demands without sacrificing efficiency during periods of lower demand is essential. Properly sizing the unit ensures that it can modulate its cooling output to match the fluctuating load, optimizing energy consumption and maintaining stable conditions within the environment.

Screw-Type Condensing Unit

English

English عربى

عربى 简体中文

简体中文