The water-cooled condenser is a crucial component in a refrigeration system, responsible for transferring heat from the refrigerant to a cooling water loop. Here's a basic explanation of how it works:

Refrigerant Compression: The refrigeration symphony commences with the compressor's powerful crescendo. This mechanical maestro orchestrates the elevation of the refrigerant from its languid, low-pressure state to a fervent, high-pressure and high-temperature composition. This compression, akin to a pressurized metamorphosis, sets the stage for the ensuing thermal drama.

Hot Refrigerant Gas: The compressed refrigerant emerges from the compressor as a blistering, high-energy gas – a veritable phoenix rising from the mechanical compression crucible. Its elevated temperature and pressure make it a formidable player in the thermal ballet, ready to dance through the ensuing acts within the water-cooled condenser.

Heat Exchange with Water: The water-cooled condenser becomes the grand stage for the ensuing thermal pas de deux. The hot refrigerant gas takes center stage, coursing through a labyrinthine coil choreography. These coils, meticulously designed, beckon the adjacent water to partake in an intricate dance of heat exchange, ensuring a symphony of efficiency in thermal transfer.

Heat Transfer to Water: As the hot refrigerant gas whirls through the coil ballet, it bestows its thermal fervor upon the surrounding water. This exchange, akin to a fiery tango, induces a transformative metamorphosis in the refrigerant. The once-fiery gas now relents, succumbing to condensation, transitioning into a liquid state.

Cooling Water Flow: Simultaneously, a deliberate and continuous cascade of cooling water envelops the coil stage. This water, reminiscent of a diligent stagehand, absorbs the radiant heat with precision, preventing any lingering warmth. Its role as the unsung hero in the thermal narrative ensures the refrigerant exits the stage with cooled composure.

Condensed Refrigerant: The climax of this thermal opera materializes as the refrigerant, having shed its gaseous bravado, condenses into a liquid. This liquid, now rich with thermal significance, emerges from the water-cooled condenser with the poise of a refined performer, ready for the subsequent acts in the refrigeration spectacle.

Liquid Refrigerant Exit: The liquid refrigerant, having traversed the fiery coils and undergone a profound metamorphosis, takes its final bow within the water-cooled condenser. It exits, stage left, prepared for an encore in the next chapters of the refrigeration epic.

Expansion Valve: The liquid refrigerant, now a veteran of the thermal opera, proceeds to the expansion valve. Here, its pressure and temperature undergo a deliberate diminuendo, a calculated modulation preparing it for a nuanced entrance into the evaporator's cooling sonata.

Evaporation in the Evaporator: Within the evaporator's cooling sonata, the low-pressure, low-temperature liquid refrigerant encounters a symphony of heat absorption. It gracefully waltzes, absorbing thermal energy from the surroundings. This dance culminates in an ethereal transformation, as the refrigerant evaporates, returning to a low-pressure gaseous state.

Return to Compressor: The cycle's denouement unfolds as the low-pressure gaseous refrigerant takes a solemn bow, returning to the compressor for an encore. The refrigeration epic thus perpetuates its cyclical performance, ensuring the sustained temperature symphony within the refrigeration system.

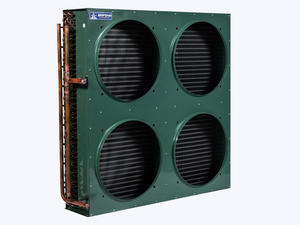

Shell And Tube Double Stage Water-Cooled Condenser

Shell And Tube Double Stage Water-Cooled Condenser

English

English عربى

عربى 简体中文

简体中文

.jpg?imageView2/2/w/300/h/300/format/jp2/q/75)