Water-cooled evaporators excel in efficiency due to the superior heat absorption properties of water compared to air. Unlike air-cooled systems that rely on ambient air to remove heat, water-cooled systems use water to absorb and transfer heat away from the refrigerant. This is particularly advantageous in high-temperature environments where air-cooled systems may struggle. By operating more efficiently, water-cooled evaporators can maintain precise temperature control with less energy consumption. This efficiency translates into a direct reduction in the amount of electricity required for cooling. As electricity generation often involves significant carbon emissions, lower energy consumption leads to a decrease in the associated greenhouse gas emissions, thereby reducing the overall carbon footprint.

Energy efficiency is a core benefit of water-cooled evaporators. They typically consume less energy to achieve the same cooling output compared to air-cooled systems. This is due to the fact that water can absorb and transfer heat more effectively than air, allowing the system to operate at lower temperatures with less energy input. Reduced energy consumption has a cascading effect on carbon emissions. Lower energy usage decreases the demand on power plants, which can result in a reduction in the burning of fossil fuels and the associated carbon emissions. In regions where the electricity grid relies heavily on coal or natural gas, this reduction can be particularly impactful.

Water-cooled evaporators can be designed to operate with lower quantities of refrigerants. Modern systems also leverage refrigerants with low Global Warming Potential, which are less harmful to the environment compared to traditional refrigerants. By using these advanced refrigerants, water-cooled evaporators can mitigate their impact on global warming. Efficient refrigerant management reduces the need for frequent refrigerant replenishment, minimizing the potential for leaks and further decreasing environmental impact.

The design and operation of water-cooled evaporators are centered around efficient heat exchange. These systems often incorporate advanced technologies such as microchannel heat exchangers, which increase the surface area for heat transfer and enhance thermal performance. Effective heat exchange ensures that the system operates at optimal conditions, reducing the need for additional energy input to achieve desired cooling levels. This optimization leads to improved overall system efficiency and a decrease in the carbon emissions associated with the energy required for cooling.

Water-cooled evaporators generally operate under cooler conditions, which reduces thermal stress on the system's components. This thermal stability contributes to a longer operational life for the equipment. Extended equipment lifespan means fewer replacements and repairs are needed, reducing the environmental impact associated with manufacturing and disposing of cooling equipment. Longer-lasting systems also lower the frequency of resource extraction and waste generation, further contributing to a reduced carbon footprint.

Water-cooled evaporators can be effectively integrated with heat recovery systems, which capture and reuse waste heat generated during the cooling process. This recovered heat can be utilized for various purposes such as pre-heating water, space heating, or even powering other industrial processes. By repurposing waste heat, the overall energy consumption of the facility is reduced, leading to lower greenhouse gas emissions. The integration of heat recovery systems enhances the sustainability of the cooling process and maximizes energy efficiency.

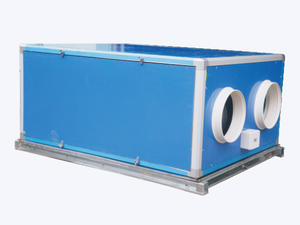

Shell And Tube Double Stage Water-Cooled Condenser

English

English عربى

عربى 简体中文

简体中文