Physical Stability: Proper installation of the condenser unit is fundamental to maintaining its stability during operation and maintenance. It's essential to ensure that the unit is securely mounted on a level and stable foundation or platform that can support its weight and withstand environmental conditions, including wind loads and seismic forces where applicable. We provide specific installation guidelines, including recommended mounting surfaces and structural supports, to prevent tipping or instability that could pose risks to personnel or equipment. Anchoring the condenser securely and using appropriate mounting hardware are critical to ensuring its structural integrity and safe operation over its service life.

Clearance Requirements: Air-cooled condensers require adequate clearance around the unit to ensure proper airflow for efficient heat dissipation and to allow safe access for maintenance personnel. Maintaining manufacturer-recommended clearance distances from walls, other equipment, and obstructions is essential to prevent airflow restrictions and potential overheating. Adequate clearance also facilitates safe access for routine inspections, cleaning, and maintenance tasks without risk of injury from moving parts or hot surfaces. Compliance with clearance requirements is crucial to ensuring the condenser's operational efficiency and preventing safety hazards associated with restricted airflow or obstructed access.

Hot Surfaces: During operation, certain components of an air-cooled condenser, such as heat exchanger coils, compressor discharge lines, and electrical components, can reach high temperatures. These hot surfaces pose burn hazards to personnel if touched accidentally. It's critical to allow sufficient time for the equipment to cool down before performing maintenance or inspection tasks that require handling or proximity to hot components. Personnel should be trained to recognize and avoid contact with hot surfaces, and appropriate PPE, such as heat-resistant gloves and clothing, should be provided and worn as necessary to protect against burns from hot equipment parts.

Refrigerant Handling: Air-cooled condensers use refrigerants, which can pose health and environmental risks if mishandled. Proper refrigerant handling procedures, including recovery, recycling, and disposal, should be followed to minimize environmental impact and ensure compliance with legal requirements. Use of appropriate PPE, such as gloves, safety goggles, and respiratory protection, is essential to prevent skin contact, eye irritation, or respiratory problems associated with exposure to refrigerants. It's critical to maintain refrigerant containment during handling and storage to prevent leaks or spills that could pose safety hazards or environmental risks.

Noise Levels: Air-cooled condensers can generate significant noise levels during operation, primarily from fan motors and airflow turbulence. Prolonged exposure to high noise levels can lead to hearing damage, making hearing protection essential for personnel working in close proximity to operating condensers. Earplugs or earmuffs should be provided and worn by personnel as appropriate to reduce noise exposure during maintenance activities or other tasks requiring proximity to noisy equipment. Noise control measures, such as installing sound barriers or scheduling maintenance tasks during quieter periods, should be considered to minimize noise exposure risks and maintain a safe working environment for personnel.

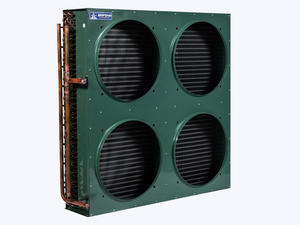

ZNT Series Evaporation Air-Cooled Condenser

English

English عربى

عربى 简体中文

简体中文