Refrigeration units have played an essential role in the food and beverage industry for over a century, revolutionizing the way we store and transport perishable goods. Prior to the development of refrigeration technology, food spoilage was a major issue, and consumers had limited access to fresh produce and other perishable items. In this article, we'll take a closer look at how refrigeration units have revolutionized the food and beverage industry.

The invention of mechanical refrigeration in the late 19th century was a game-changer for the food industry. Suddenly, fresh produce, dairy products, and meats could be transported across long distances without spoiling. This made it possible for food producers to expand their markets and reach consumers in distant regions. Refrigeration also made it possible to store large quantities of food for longer periods of time, reducing waste and increasing efficiency in the industry.

Over the years, refrigeration technology has continued to evolve and improve, with the development of new materials and innovations that have made refrigeration units more efficient and cost-effective. Today, refrigeration units are used in a wide range of applications, from small residential units to massive industrial systems that can store and transport large quantities of food and beverages.

One of the key benefits of refrigeration units is that they help to ensure the safety and quality of food products. By maintaining consistent temperatures, refrigeration units help to prevent the growth of harmful bacteria and other pathogens that can cause foodborne illness. This is especially important in the food industry, where food safety is a top priority.

In addition to improving food safety, refrigeration units have also made it possible for the food industry to operate more sustainably. By reducing food waste and improving efficiency, refrigeration units help to minimize the environmental impact of the industry.

Overall, refrigeration units have revolutionized the food and beverage industry, making it possible to transport, store, and preserve perishable goods in ways that were once impossible. As the technology continues to evolve, we can expect even more innovations and improvements that will continue to transform the industry.

Features of Before semi-hermetic compressor units Usability:

• The compressor unit can for use in many kinds of refrigerants such as R22, R134a, R404, R407C.

• The same serial compressor unit, is suitable for different applications.

Excellent functions:

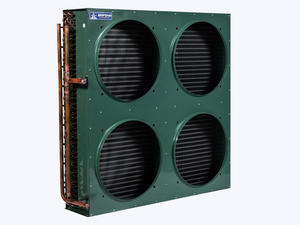

• Equipped with oil separator, high and lower pressure controller, solenoid valve, filter drier, high and lower pressure gauge, big volume receiver and high efficient condensing units, it is good match unit.

Special design for the construction:

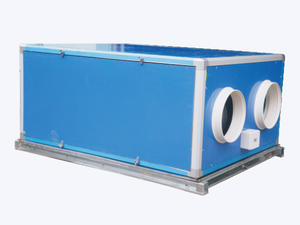

• Construction compact, equipped with protect cover,stability, service life long and good looking.

• Excellent design for the driving parts to rduced the vibration result.

• The reasonable suction device in order to compressor cylinder has completed cooling.

• According to different applications to equipment with high efficient Wpattern Rifle bored copper, it can be reduced overall dimension and add transfer-heating result.

• BFBV20 over 56H(Y) compressor unit adopted split wire motor, it can use small current to start running.

Reliability protectors:

• The motor uses electronic module protector or advanced heat protector to control the temperature.

• BFBV20 over 84.5H(Y)compress unit or adopted oil different pressure controller to ensure well lubrication system and equipped with auto-proctor of high pressure release valve.

• Crankcase heater fitted to prevent liquid migration.

English

English عربى

عربى 简体中文

简体中文

.jpg?imageView2/2/w/300/h/300/format/jp2/q/75)