The capacity control mechanism in semi-hermetic compressors is essential for adapting to varying load demands and ensuring efficient operation. The most common methods for capacity control in semi-hermetic compressors include:

1.Displacement Control: Displacement control is all about tweaking how much refrigerant gas gets sucked into the compressor, directly influencing its displacement or ability to pump refrigerant.

The suction modulation valve, usually located in the suction line, is the key player here. It adjusts its aperture based on the system's cooling needs, effectively managing the flow of refrigerant into the compressor to control capacity.

2.Cylinder Unloading: Semi-hermetic compressors with multiple cylinders have this nifty trick of selectively taking some cylinders offline, reducing the compressor's overall capacity.

Solenoid valves play a crucial role by strategically opening or closing refrigerant pathways to individual cylinders. This unloading process optimizes efficiency by tailoring the compressor's power to the specific cooling demand.

3.Variable-Speed Drive (VSD): Variable-Speed Drives (VSD) offer a dynamic dance with the compressor motor speed, giving granular control over the refrigerant flow and, in turn, the compressor's capacity.

Adjusting the frequency of the electrical power supplied to the motor, the VSD system regulates the speed of the compressor motor. This isn't just a binary on/off situation; it's a smooth, continuous adjustment providing unparalleled efficiency under varying load conditions.

4.Hot Gas Bypass: Hot gas bypass is like a safety valve for the compressor, diverting some of the high-pressure, hot refrigerant gas back into the suction line to scale down the overall capacity.

Controlled by a bypass valve, this method ensures that during low-load scenarios, the compressor doesn’t go through the wear and tear of frequent cycling. It’s a stabilizing act to maintain a steady and controlled operation.

Adjusting the capacity control mechanism is crucial to optimize the performance of a semi-hermetic compressor based on the specific cooling or refrigeration needs. The adjustment methods depend on the compressor's design and the installed capacity control system. Here are some common ways to adjust capacity:

1.Setpoint Adjustment: Setpoint adjustment lets you finely tune the system’s behavior by configuring specific operational conditions and desired capacity levels through the electronic controls.

Tweak those pressure and temperature setpoints, and other critical control parameters, aligning the compressor's performance with your exact requirements. It’s the conductor's wand in the symphony of system optimization.

2.Control Signal Adjustment: For systems with electronic or digital controllers, control signal adjustment is like tweaking the strings on a guitar, influencing the compressor's capacity modulation.

By playing with input signals, users can fine-tune the responsiveness of the compressor to changes in the cooling load, ensuring it dances smoothly to the rhythm of your operational needs.

3.Motor Speed Adjustment: Compressors with variable-speed drives empower you with direct control over the motor speed, a game-changer for adjusting the compressor's capacity with surgical precision.

Technical Empowerment: Through the control interface provided by the variable-speed drive system, users can unleash the full potential of the compressor by adjusting the motor speed, offering unparalleled control over refrigerant flow and system capacity.

Regular monitoring and adjustment of the capacity control mechanism are essential for maintaining energy efficiency and ensuring that the semi-hermetic compressor operates within its design parameters across varying load conditions.

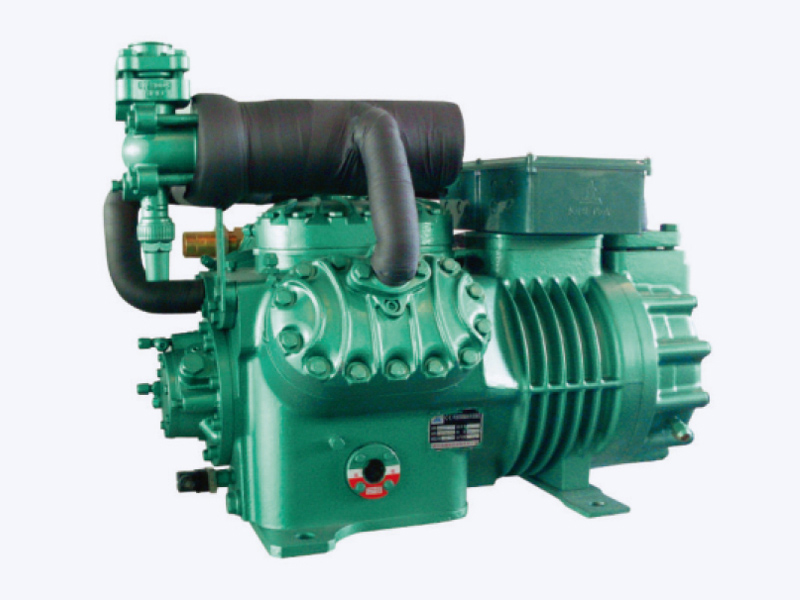

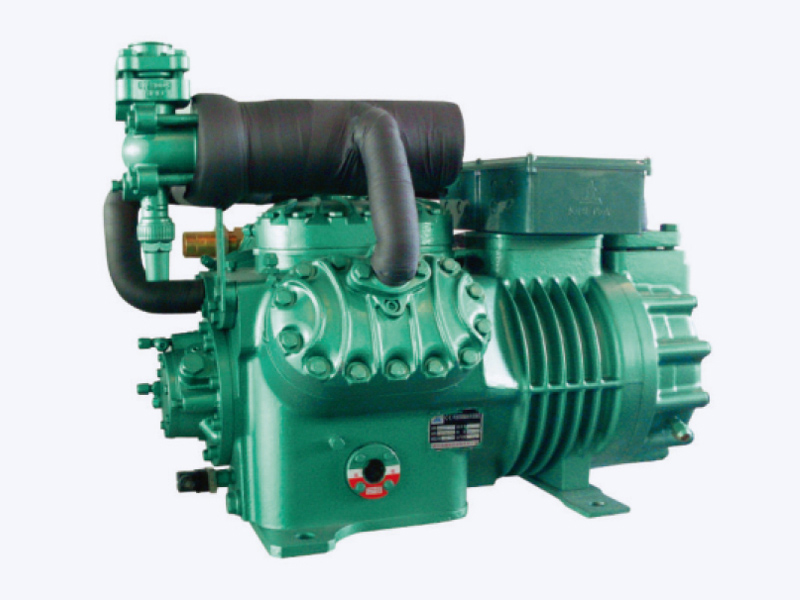

Semi-Hermetic Two-Stage Compressor

Semi-Hermetic Two-Stage Compressor

English

English عربى

عربى 简体中文

简体中文

.jpg?imageView2/2/w/300/h/300/format/jp2/q/75)

.jpg?imageView2/2/w/300/h/300/format/jp2/q/75)