11

Apr

The handling of environmental factors such as temperature, humidity, and dust by a Box-Type Unit depends on its design and specifications. Here are some considerations:

Temperature Regulation: Box-Type Units are equipped with sophisticated temperature management systems that go beyond basic heating and cooling mechanisms. These systems often employ advanced algorithms and feedback loops, constantly monitoring internal and external temperatures through an array of sensors strategically positioned within the unit. Based on real-time data, the system dynamically adjusts heating elements, cooling fans, or refrigeration cycles to maintain temperatures within precise tolerances. Supplementary features such as thermal insulation blankets or phase change materials may be integrated to enhance thermal inertia, ensuring minimal temperature fluctuations even in the face of rapid environmental changes.

Humidity Management: Beyond simple dehumidifiers, Box-Type Units utilize state-of-the-art humidity control technologies tailored to specific environmental conditions. Advanced desiccant systems leverage hygroscopic materials with high moisture absorption capacities, effectively extracting water vapor from the air. Alternatively, refrigeration-based dehumidifiers utilize condensation principles to remove excess moisture, producing dry air streams that are reintroduced into the enclosure. In applications where precise humidity control is paramount, sophisticated humidity sensors and controllers maintain humidity levels within narrow bands, preventing both excessive drying and moisture buildup.

Dust Protection: Dust mitigation strategies employed in Box-Type Units extend far beyond basic filtration systems. High-efficiency particulate air (HEPA) filters, rated for capturing particles as small as 0.3 microns, are commonly utilized to maintain pristine air quality within the enclosure. In addition to primary filtration, pre-filters and electrostatic precipitators may be employed to capture larger particles and electrostatically charge airborne contaminants, enhancing filtration efficiency. Advanced sealing technologies such as labyrinth seals, double-lip seals, and positive pressure enclosures create multiple barriers against dust ingress, ensuring a hermetically sealed environment for sensitive electronics.

Enclosure Design Considerations: The design of Box-Type Unit enclosures is a meticulous process that considers a myriad of factors to ensure optimal performance and durability. Materials selected for enclosure construction undergo rigorous testing for mechanical strength, corrosion resistance, and thermal stability. For outdoor applications, marine-grade stainless steel or aluminum alloys with high corrosion resistance are often chosen to withstand exposure to salt spray and UV radiation. Advanced sealing techniques such as compression-molded gaskets, tongue-and-groove joints, and welded seams create an impermeable barrier against environmental contaminants, maintaining a clean and controlled internal environment.

Comprehensive Testing Protocols: Prior to commercial release, Box-Type Units undergo an exhaustive battery of environmental tests to validate their performance under extreme conditions. Temperature cycling tests subject units to rapid temperature changes, simulating thermal stresses encountered in real-world applications. Humidity chamber tests assess the unit's resistance to moisture ingress and condensation formation under high-humidity conditions. Dust ingress tests, conducted in specialized dust chambers, evaluate the unit's ability to prevent particulate intrusion under varying particle sizes and concentrations. Accelerated aging tests simulate prolonged exposure to environmental factors, ensuring long-term reliability and durability.

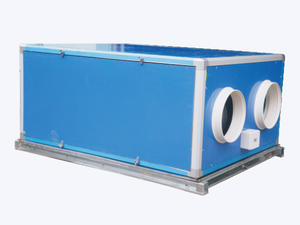

Model L CUB Box-Type Unit

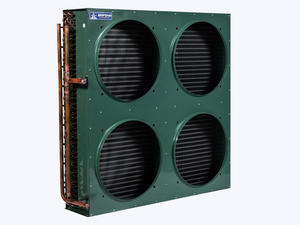

BF-CU series outdoor condensing unit Apply to all kinds of high,Temperature of the cold storage, the Display ark,storage,Industrial equipment, etc.According to industry within Different customers,Points 3 kinds of products The BF-CUA ordinary series, The BF-efficient series, don The BF-CUC ejector wind series.

Temperature Regulation: Box-Type Units are equipped with sophisticated temperature management systems that go beyond basic heating and cooling mechanisms. These systems often employ advanced algorithms and feedback loops, constantly monitoring internal and external temperatures through an array of sensors strategically positioned within the unit. Based on real-time data, the system dynamically adjusts heating elements, cooling fans, or refrigeration cycles to maintain temperatures within precise tolerances. Supplementary features such as thermal insulation blankets or phase change materials may be integrated to enhance thermal inertia, ensuring minimal temperature fluctuations even in the face of rapid environmental changes.

Humidity Management: Beyond simple dehumidifiers, Box-Type Units utilize state-of-the-art humidity control technologies tailored to specific environmental conditions. Advanced desiccant systems leverage hygroscopic materials with high moisture absorption capacities, effectively extracting water vapor from the air. Alternatively, refrigeration-based dehumidifiers utilize condensation principles to remove excess moisture, producing dry air streams that are reintroduced into the enclosure. In applications where precise humidity control is paramount, sophisticated humidity sensors and controllers maintain humidity levels within narrow bands, preventing both excessive drying and moisture buildup.

Dust Protection: Dust mitigation strategies employed in Box-Type Units extend far beyond basic filtration systems. High-efficiency particulate air (HEPA) filters, rated for capturing particles as small as 0.3 microns, are commonly utilized to maintain pristine air quality within the enclosure. In addition to primary filtration, pre-filters and electrostatic precipitators may be employed to capture larger particles and electrostatically charge airborne contaminants, enhancing filtration efficiency. Advanced sealing technologies such as labyrinth seals, double-lip seals, and positive pressure enclosures create multiple barriers against dust ingress, ensuring a hermetically sealed environment for sensitive electronics.

Enclosure Design Considerations: The design of Box-Type Unit enclosures is a meticulous process that considers a myriad of factors to ensure optimal performance and durability. Materials selected for enclosure construction undergo rigorous testing for mechanical strength, corrosion resistance, and thermal stability. For outdoor applications, marine-grade stainless steel or aluminum alloys with high corrosion resistance are often chosen to withstand exposure to salt spray and UV radiation. Advanced sealing techniques such as compression-molded gaskets, tongue-and-groove joints, and welded seams create an impermeable barrier against environmental contaminants, maintaining a clean and controlled internal environment.

Comprehensive Testing Protocols: Prior to commercial release, Box-Type Units undergo an exhaustive battery of environmental tests to validate their performance under extreme conditions. Temperature cycling tests subject units to rapid temperature changes, simulating thermal stresses encountered in real-world applications. Humidity chamber tests assess the unit's resistance to moisture ingress and condensation formation under high-humidity conditions. Dust ingress tests, conducted in specialized dust chambers, evaluate the unit's ability to prevent particulate intrusion under varying particle sizes and concentrations. Accelerated aging tests simulate prolonged exposure to environmental factors, ensuring long-term reliability and durability.

Model L CUB Box-Type Unit

BF-CU series outdoor condensing unit Apply to all kinds of high,Temperature of the cold storage, the Display ark,storage,Industrial equipment, etc.According to industry within Different customers,Points 3 kinds of products The BF-CUA ordinary series, The BF-efficient series, don The BF-CUC ejector wind series.

English

English عربى

عربى 简体中文

简体中文