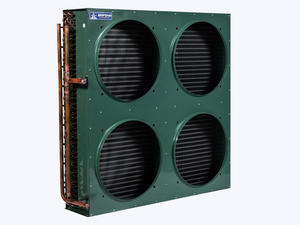

The term air-conditioned condenser refers to a cooling unit that uses an electric fan and an evaporator to cool a medium with water or air. In most systems between heat exchange, acondenser is an evaporator used to condensed a gaseous material to a liquid form through refrigeration. In this way, it absorbs and compresses the gaseous form of the element and releases its heat into the ambient environment. Air-Conditioned Condenser in refrigeration systems are generally placed in front of or behind the appliance.

There are two kinds of cooling towers: Direct Air Cooling Tower (DAC) and Air-Cooled Condenser. In AC tower cooling system, a series of heat exchangers (or a single one) are located in the tower and these exchangers are filled with cold water which passes through these heat exchangers. AC compressors also use the same sort of principle. However, unlike the AC tower model, air-cooled condenser uses a small refrigerant to cool the tower only.

Air-Cooled condenser or evaporator is generally found in combined-cycle power plants and in small scale refrigeration applications. In this type of cooling tower, air is compressed by an Electric Membrane (ductwork) in order to draw in cooled water vapor from the atmosphere. The process of condensation is reversed by the addition of a second refrigerant, typically a Freon, to enhance the cooling effect. Air-Conditioned Condenser is also used in hydronic furnaces and in some desalination plants. It has become popular in both commercial and residential applications because of its ability to operate efficiently in all types of conditions.

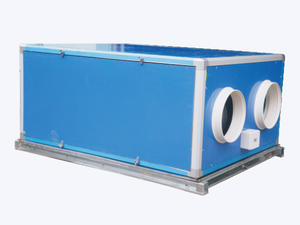

An Air-Conditioned Condenser can be of two types: open or closed. A closed air-conditioning condenser has no ventilation and the cooling fluid is circulated inside the building instead of going out through the vents. This type has obvious advantages over the open type, especially in highly variable climate areas where sudden extreme heat and cold could cause unbearable discomfort and even kill people. On the other hand, the disadvantage is that it has less flexibility; because the temperature inside the building cannot be changed much, the systems have to run constantly to keep up with changing temperatures.

A more flexible kind of Air-Conditioned Condenser includes a fan that draws warm or cool air into the condenser coil inlets. Warm air enters first and then cool air is drawn in later. A variety of cooling techniques can be used, depending on the size of the core or coil. In some cases, a low pressure blower that can also pull warm air in can be used. Air-Conditioned Chiller for residential use should have a fan that runs continuously to keep the cooling constant and running efficiently.

Dry Cooling is another common cooling technique used by Air-Conditioned Condensers to conserve energy. However, in dry cooling, the cooling liquid is circulated using a pipe that sends the water vapor in a closed system. Some Air-Conditioned Condensers are equipped with a desuperheater that uses steam to absorb heat from the environment in order to produce cold water vapor. This process is more efficient than the conventional dry cooling, but it consumes more power. If you are considering installing an Air-Cooled Condenser in your office or other structure, it is always better to consult a qualified technician to install it properly.

English

English عربى

عربى 简体中文

简体中文

.jpg?imageView2/2/w/300/h/300/format/jp2/q/75)