There are many types of compressors for industrial chillers, which can meet the needs of different use environments. In order to achieve better-operating results, many domestic industrial chiller manufacturers have chosen to use screw compressors. All production tasks to achieve the purpose of improving the overall production efficiency.

The specific classification of the compressor of the screw type industrial chiller

1. Open compressor

This type of compressor is widely used. Many domestic industrial chillers use open-type compressors as the main core accessories. Since the main working mode of open-type compressors is the high-speed operation realized by the connection between the dragon coupling and the motor, therefore Daily effective lubrication and maintenance can prevent the open compressor from leaking refrigerant and lubricating oil, etc., and greatly extend the service life of the industrial chiller.

3. Hermetic compressor

The main production technology of hermetic compressors is to enclose the motor and compressor in the container, and all the use effects can be completed in the entire container. At the same time, because it is in a fully enclosed state, the noise control is very good. For higher users, it is very good to buy a hermetic compressor. On the premise of ensuring power, a more comfortable and quiet operating environment can be obtained.

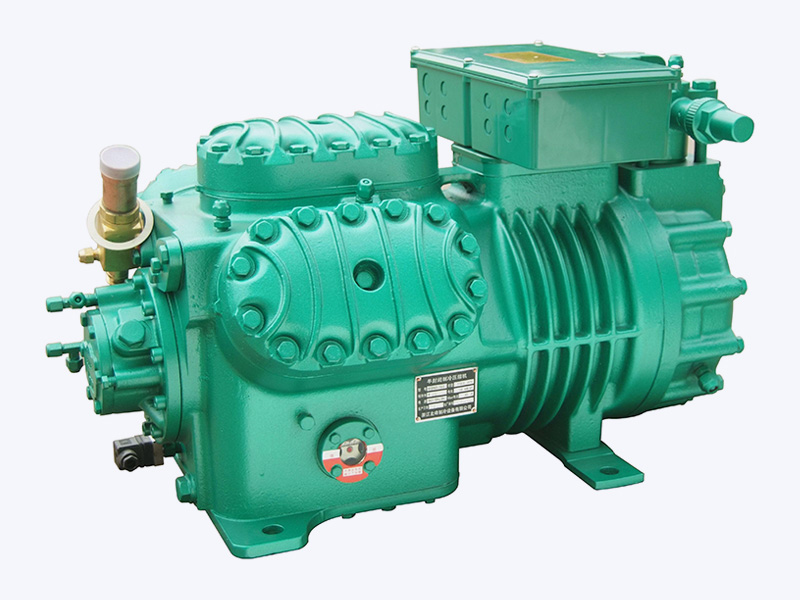

The semi-hermetic compressor perfectly integrates the motor and the compressor during the production process, so it can prevent the leakage of various lubricants and refrigerants in the compressor. In the actual use process, we can feel the semi-hermetic compressor. The function of the compressor is relatively complete, which can meet the needs of different shifts, and effectively improve the overall operating efficiency.

Semi-Hermetic Compressor(15HP-50HP)

Usability:

•The same serial compressors are available for many kinds of refrigerants such as R134a, R404a, R407C and R22

•The same serial compressors are suitable for different operating temperatures.

English

English عربى

عربى 简体中文

简体中文